Meadow.Foundation.Servos.Servo

| ServoCore | |

|---|---|

| Status |  |

| Source code | GitHub |

| Datasheet(s) | GitHub |

| NuGet package |  |

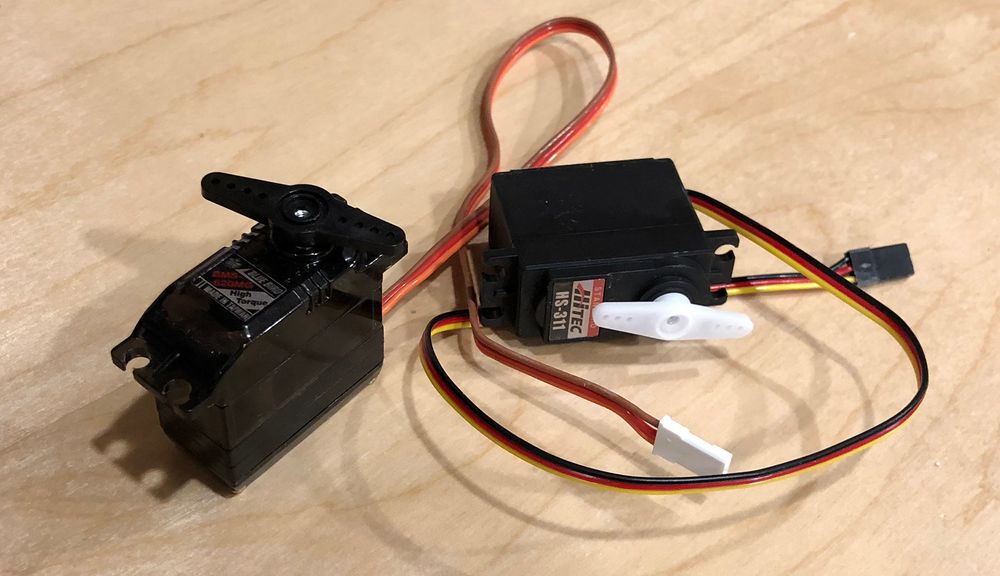

Servos are integrated packages that usually include a DC electric motor, torque-increasing gearing, and electronics to control the motor:

The gained their popularity as an important part of remote controlled cars, airplanes, and such, but are now also very common in robotics.

Unlike simple electric motors, they have three wires, with two wires supplying power, and the third wire accepting a PWM control signal.

Types of Servos

There are two types of servos; fixed-angle servos, and continuous rotation servos.

Fixed-Angle Servos

Fixed angle servos are by far the most common type of servo, and usually what people mean when they use the term servo. They can only move within a given range, most commonly between 0º and 180º. The integrated electronic control system in a servo allows them to be controlled very precisely, so that you can set them to turn to a specific angle.

Continuous Rotation Servos

Continuous rotation servos are sometimes known as winch servos, because they were originally used as winch controls on remote control sailboats. They don't have any restriction on their angle of movement, but instead will rotate in either clockwise or counter-clockwise direction at a set speed.

Control Signal

Both fixed-angle and continuous rotation servos are controlled with a PWM signal, and the duration of the duty cycle pulse determines their behavior.

Every servo has a minimum pulse duration and a maximum pulse duration that they respond to. A control signal outside of this range will usually be ignored by the servo. The ideal standard is a minimum of 1.0ms and a max of 2.0ms, but in practicality, many servos have a much wider range of operation. Additionally, because the pulses vary between fractional milliseconds, µseconds (1,000 milliseconds) are usually used as the unit. So a 1.0ms pulse is 1,000µs.

Fixed Angle Control

For fixed-angle servos, the minimum pulse duration will cause them to rotate to their minimum angle (nominally 0º), and the maximum pulse duration will rotate them to their maximum angle. So for instance, the following table describes the rotation of a 180º servo that has a pulse range of 1,000µs to 2,000µs:

| Control Pulse | Angle |

|---|---|

1,000µs | 0º |

1,500µs | 90º |

2,000µs | 1800º |

Continuous Rotation Control

Continuous rotation servos still have a minimum and maximum pulse durations, but they work a little differently. At the midpoint between those extremes, a control signal will actually stop the servo, and anything less than that midpoint will cause it to rotate clockwise, and anything more than that midpoint will cause it to rotate counter-clockwise. And the distance from that midpoint controls the speed of rotation. For example, the following table describes rotation and speed of various control signals:

| Pulse Duration | Rotation Direction | Speed |

|---|---|---|

1,000µs | Clockwise | 100% |

1,250µs | Clockwise | 50% |

1,500µs | None | n/a |

1,750µs | Counter-Clockwise | 50% |

2,000µs | Counter-Clockwise | 100% |

Powering Servos

Servos can draw a lot of current, especially under load. Additionally, most common hobby servos require 6V. For this reason, an external power supply should be used when they're used in practical applications.

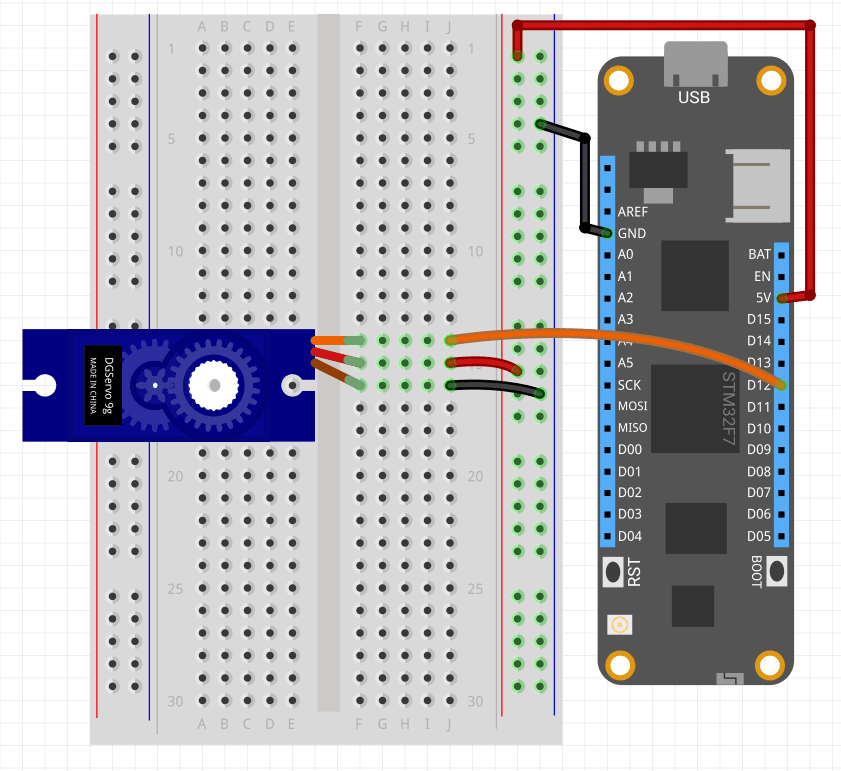

For just testing however, they can be powered via the 5V rail on the Meadow as follows:

Testing Circuit

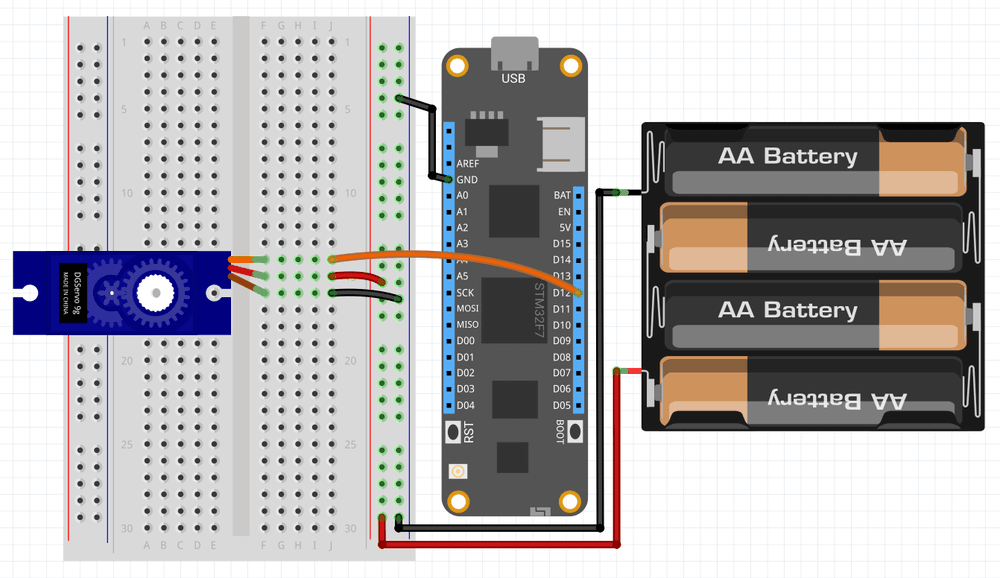

External Power Circuit

When powering with an external power source, you must connect the external GND to the GND rail on the Meadow (as shown in the following schematic and breadboard illustration), or the PWM control signal will not work:

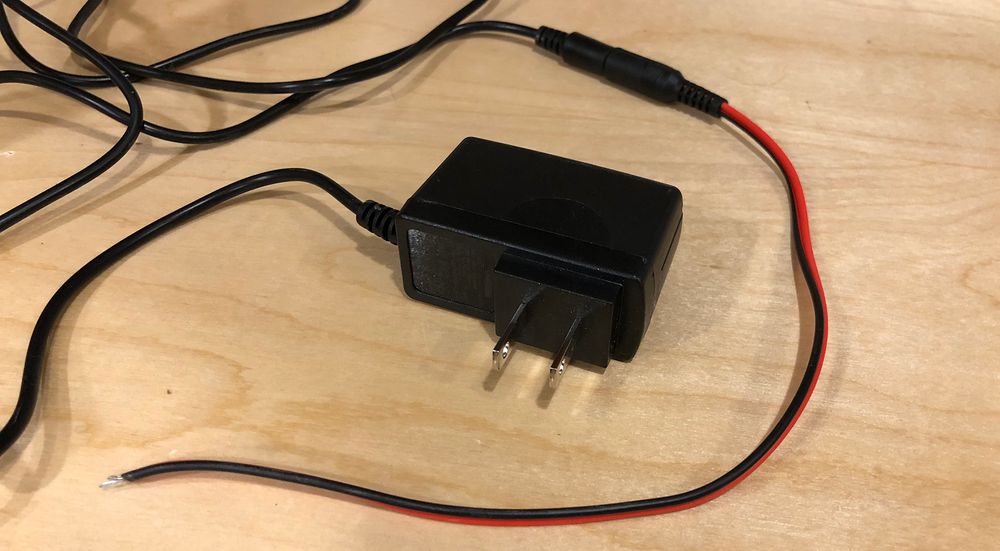

In the above illustration, (4), AA batteries are used, but we usually use a power supply like the following:

Cable Colors

Servo cable colors vary by manufacture, but they're always in the same order. The GND pin is the first pin by convention is always the darkest:

| Pin | Signal | Futaba Colors | HiTec Colors | JR Colors |

|---|---|---|---|---|

| 1 | GND | Black | Black | Brown |

| 2 | VCC | Red | Red or Brown | Red |

| 3 | Control | White | Yellow or White | Orange |

Code Example

protected Servo servo;

public override Task Initialize()

{

Resolver.Log.Info("Initialize...");

servo = new Servo(Device.Pins.D02, NamedServoConfigs.SG90);

return Task.CompletedTask;

}

public async override Task Run()

{

await servo.RotateTo(new Angle(0, AU.Degrees));

while (true)

{

for (int i = 0; i <= servo.Config.MaximumAngle.Degrees; i++)

{

await servo.RotateTo(new Angle(i, AU.Degrees));

Resolver.Log.Info($"Rotating to {i}");

}

await Task.Delay(2000);

for (int i = 180; i >= servo.Config.MinimumAngle.Degrees; i--)

{

await servo.RotateTo(new Angle(i, AU.Degrees));

Resolver.Log.Info($"Rotating to {i}");

}

await Task.Delay(2000);

}

}

Sample project(s) available on GitHub

Class Servo

Class to represent a generic servo motor

Assembly: ServoCore.dll

View Source

public class Servo : AngularServoBase, IAngularServo, IServo

Inheritance: System.Object -> Meadow.Foundation.Servos.ServoBase

Implements:

Meadow.Foundation.Servos.IAngularServo